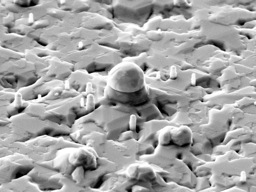

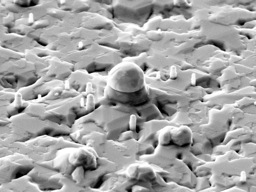

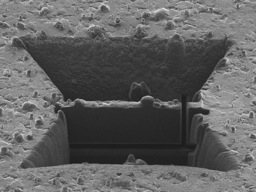

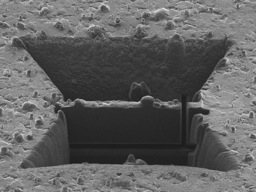

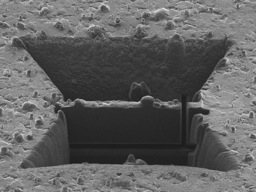

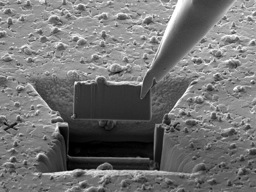

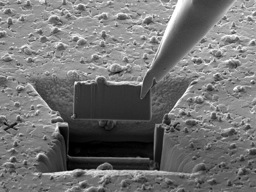

Feature of interest

The feature of interest is located with the Scanning Electron Microscope (SEM) in the FIB/SEM CrossBeam.

(Sample courtesy of Prof. Ray La Pierre, McMaster University).

(Sample courtesy of Prof. Ray La Pierre, McMaster University).

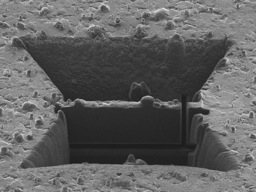

FIB mill

The region of interest is coated with platinum, in-situ, using the CrossBeam’s gas injection system. This layer protects the surface of the feature during subsequent FIB milling. The surrounding substrate is removed by FIB milling, leaving a 1 micron thick lamella containing the feature of interest.

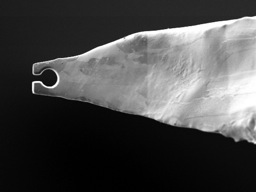

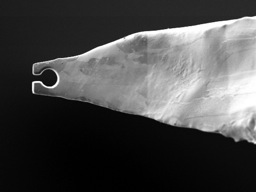

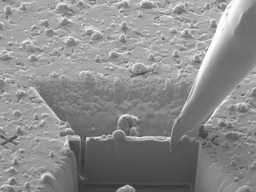

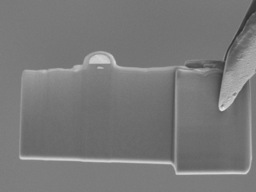

Nanomanipulator

At the tip nanomanipulator rod is mounted an ‘end effector’ – a sharp Mo or Cu tip. The tip is positioned just above the region of interest on the sample.

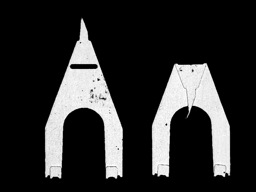

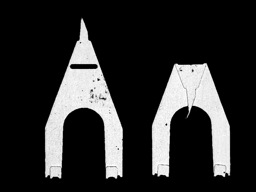

Prepare tip

Using the FIB, a pair of tines are machined at the tip of the end effector. The spacing is slightly less than the thickness of the lamella.

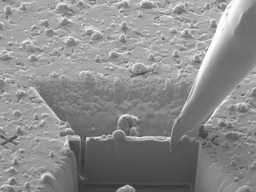

Undercut

The left and bottom sides of the lamella cut free.

Grab the sample

The end effector is positioned onto the right side of the lamella. This procedure is accomplished by viewing both the SEM and FIB secondary electron images while lowering the end effector onto the sample. The alignment of the tines with the sample in plane of the sample surface is observed and adjusted in the FIB image and the height is visualized in the SEM image.

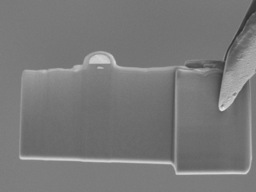

Pluck the sample

With the lamella securely held between the tines, the right side is cut free and the sample is lifted clear, again while monitoring the position with both the FIB and SEM electron images.

Final thinning

After the lamella is lifted clear of the substrate, the final thinning and polishing is performed by FIB milling. Progress is monitored in situ by SEM – the rod can be rotated to allow both front and back to be imaged and the thickness to be measured. A final thickness of 150nm is routine. Thinner foils can be produced depending on the mechanical stability of the material.

Ready for TEM

The nanomanipulator rod is withdrawn from the microscope through a loadlock without venting the microscope chamber. After the tip of the end effector is folded over and removed from the nanomanipulator rod, it can be directly mounted in a standard 3mm diameter TEM sample holder.